The food & beverage digest

Appetising ideas to help improve your food and beverage production

The digest is continually updated, so don't forget to bookmark the page and check back regularly for more digital transformation ideas.

Flexible manufacturing: Adapting quickly to changing markets and events

Technology alone cannot create the agility you need to respond to today’s volatile market conditions. Here are the five essential areas you need to develop for more flexible operations.

Deliver what they want

With personalised products and customised delivery becoming the norm, here’s how independent cart technology can help you vary product and packaging formats to deliver multiple SKUs.

Are you challenging machine builders to think differently?

Meeting demand for rapidly increasing SKUs can be tough. Read why changing the way you work with OEMs can ensure your people make the right decisions, your production line runs smoothly and your changeovers are fast.

Meet changing demands with flexible manufacturing

How do you establish flexible operations that can adapt to the market with new products and solutions? Watch our Industry Forum webinar for insight into how you can improve your efficiency, profitability and flexibility.

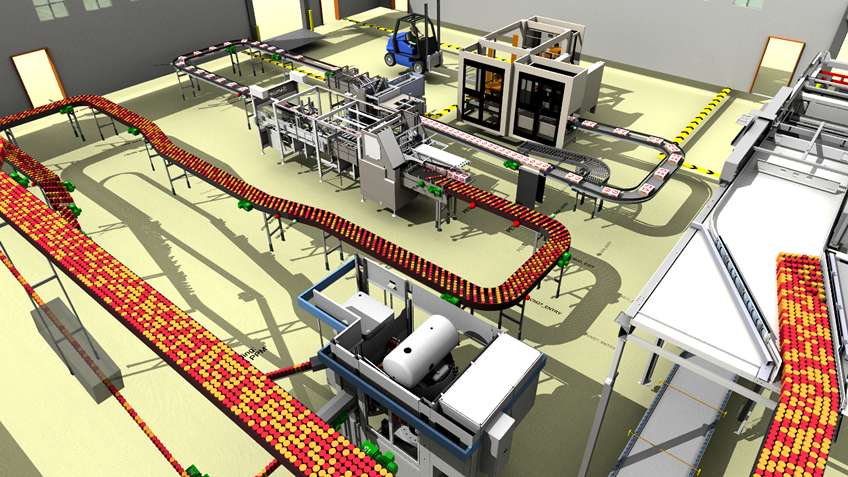

Digital twin: The future and now of human and machine interaction

With digital twins becoming an ever-present industry buzzword, watch our quick explainer video about their impact on industrial machine design and potential for accurately predicting future operations.

Add emulation to your speed to market toolbox

Bringing new products to market always involves having to accept some risk. But as consumer demand continues to shift, read why emulation technology can improve speed to market without compromising production.

Delicious Data: How Predictive Analytics Improves Efficiency

The information you need to improve your productivity is already available in your facility. In this blog, we look at how three major food and beverage producers accessed this hidden data to make measurable improvements to their manufacturing processes.

Mondeléz Rolls Out its Integrated Digital Factory

Mondeléz International recently sought to bring the power of real-time data to 14 of its factories to help deliver more personalised consumer choice, faster, cheaper and more efficiently. Discover how its data-enabled factory floor programme has improved OEE by up to 5%.

See and Solve Failures Before They Happen with Predictive Analytics

When it comes to spotting machine or equipment failures, it is not enough to know straight away. In this blog we explore how predictive analytics combine real-time data and machine learning to provide insights into issues before they cause downtime.

Global Food Leader Begins The Journey to the Connected Enterprise

For one iconic food and beverage company, converging its IT and OT systems across several global sites was the key to reducing downtime through remote monitoring. Read how the company was able to improve production and reduce emissions, energy, water usage and waste.

The real-world impact of digital twins and AR

How could a digital twin and augmented reality impact your operations in the real world? This video shows how Cama, a world leading packaging machine manufacturer, has improved operator skills and plant performance on everything from machine design to maintenance

Cybersecurity in a crisis – what should you be doing?

Flexibility in manufacturing is important, but one area where you cannot relax is cybersecurity. In this blog, we explain how to protect your business from the scammers who capitalise on a crisis.

Strengthen your cybersecurity in Smart Manufacturing

As your operations become more connected, there are many security risks you might not have considered. Here’s a white paper that explains the cybersecurity threats facing food and beverage producers, with information that has only become more relevant as time has progressed.

Video: How to start protecting your facility immediately

What practical cybersecurity steps can you take to start protecting your food and beverage facility immediately? In this short video, our director of IT/OT security strategy explains the most critical aspects of getting started with a robust policy.

Webinar: How to protect against increasing cyber-attacks

In this webinar, we explain the challenges facing manufacturers and how they can be addressed by developing a proactive approach to industrial cybersecurity.

Let's talk! Request a complimentary discovery session

Where does your facility’s cybersecurity need support? When it comes to protecting your facility, sometimes it’s better to have a one-on-one conversation. To discuss tangible ideas for improving your cybersecurity, sign up for a complimentary discovery session with one of our experienced industrial security professionals.